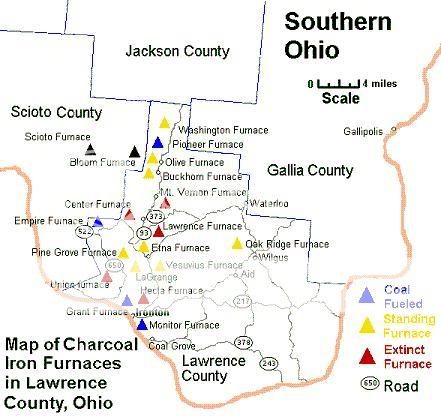

The Hanging Rock Iron Region comprised an area of country

embracing more than 1,000 square miles, extending into the States

of Kentucky and West Virginia, and Scioto, Lawrence, Jackson and

Vinton counties in Ohio, with its center at Ironton. This vast

mineral region contained valuable iron ores, large and accessible

deposits of coal, limestone and fire-clays.

Hanging Rock Iron Region had the honor of being the site of the

first major expansion of iron manufacturing in the United States.

This was due to the discovery of a bonanza of iron ore in the early

1800s. The ferriferous iron ore, often a foot thick, laid

immediately on top of iron rich limestone. Outcroppings along the

hillsides led to easy discovery of this important element. It was

much more than heretofore had been found anywhere in the

continental United States.

Geologists say that the purity of the iron ores in this district

were attributable to the fact that the plane of the veins or

"horizons" laid far enough above the general water level to drain

the water that accumulated from the rain fall, through the minerals

and out into the streams. The dip of the strata is reported to be

about 30 feet to the mile to the south of east giving the

inclination of all coal and ore horizons a rapid fall in the

direction of the dip. This made it possible for miners to run all

material out on tram tracks by gravitation, as well as to get rid

of the water without expense.

The Hanging Rock ores were peculiarly adapted to the production

of an iron of great strength and durability. They were said to be

of the red hematite variety-the "hilltop" ores being largely used

with underlying limestone ore. Furnace Managers recognized several

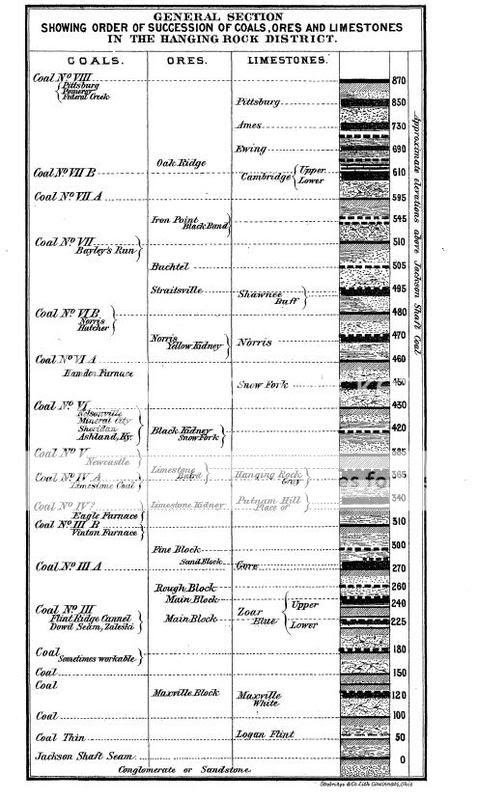

important seams of ore here in well known and consistent horizons

that followed the margin of the coal horizons recorded from early

geologic surveys. The ferriferous limestone was rated high in value

and persistency.

The coal seams were valuable guides in following the horizons

from point to point. When the limestone, coal and ore were all

brought into horizontal alignment for miles without interruption,

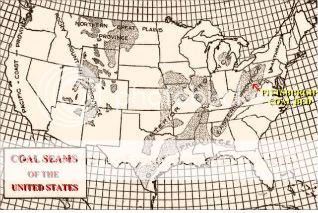

their symmetrical order was pronounced. The coal measures of Ohio

are important sources of iron ore and fire-clay as well as of coal,

as is true of coal measures generally. Iron ore was mined in the

Ohio coal-fields at a dozen or more horizons, but there are three

or four that monopolize most of the interest and importance. The

ferriferous limestone ore of the Hanging Rock district was a thin

but valuable seam. The iron manufactured from it has unusual

strength and excellence and was applied to the highest uses.

The ores of the Hanging Rock Region can be divided

stratigraphically into three natural groups. The lowest horizon

extends from the Carboniferous Period and is a limestone used as

block ore. The second division is the ferriferous limestone horizon

which is a central feature of the whole district. The third horizon

is the sandstone which extends some 150' above the limestone in

most of the region. The coal horizons can be followed southward and

westward from the Pennsylvania line and can be traced with

unmistakable distinctness from Jackson County into Scioto and

Lawrence Counties to the Ohio River.The limestone horizon was by

far the most important one of the series and is one of the most

well marked and persistent features of the geology of the Hanging

Rock Region.

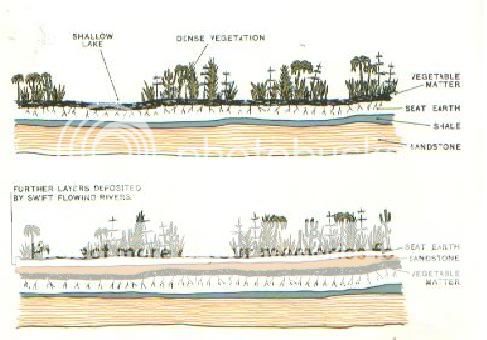

The native iron ores that account for the success of the

furnaces of the region are derived from the Lower Coal Measures and

accumulated under the same general conditions- as carbonates of

iron in the marshes and swamps of the Carboniferous Period during

Mississippian and Pennsylvanian Periods of the Paleozoic Era. They

were stratified or concretionary or chemical formed ores. The coals

formed near sea level. The fossil filled limestone formed upon the

sea floor in warm and clear water. Sandstones comprise the flesh

and bones of decaying animals and were of deltaic deepwater

creation.

The lowest deposit of ore is generally found near the lowest

coal seam. The lowest coal seam or horizon here was

Sub-Carboniferous Period Age. The limestone horizon will follow the

coal seams intermittently throughout the horizon. Sandstone

generally lies at the top of formations from creation during deeper

water conditions. The most pronounced coal seam on the geologic

horizon in Southern Ohio is the #6 Coal. Valuable fire clay

generally was heavily underlain by Coal #3 seams.

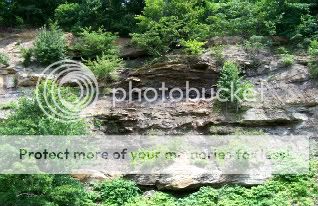

The ores of the Coal Measures are of great economic importance

and have been called the "economic horizons" geologically. The

horizon formations can be traced with the eye in unbroken outcrop

for mile after mile here. They include sandstone ledges, beds of

coal, flint and fire clay, and seams of ore and limestone strata.

The heavy sandstone that covers Coal #6 throughout the region

outcrop is very visible along the Ohio River. Near the Village of

Hanging Rock it shows itself in a bold and picturesque escarpment

that time has weathered in the form of a rock overhang from which

the village derived it's name.

The coal horizons are perhaps the most trusted and used in

marking other horizons. Reliance in their quality are generally

found to be consistent. Similarly with the fire clays. It is with

the limestone horizon that difference in quality can be found. The

limestone tend to be more individualized by region. Thus

distinguishing the Hanging Rock Region for great quality for the

production of iron when other locations of similar time and period

limestone was not as good quality.

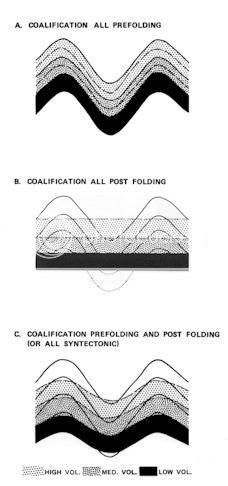

Geologic studies in the Appalachian region have shown that many

parameters of coal beds (thickness and continuity, sulfur and

trace-element content, and ash) can be attributed to the

depositional environment in which the peat beds formed and to the

tectonic setting at the time of deposition. With an understanding

of the depositional setting of the coal seam and contemporaneous

tectonic influences, the characteristics and variability of many of

these parameters can be predicted.

Coals formed in "back-barrier" environments tend to be thin,

laterally discontinuous and high in sulfur. Coal beds deposited in

the "lower delta-plain" environment are relatively widespread with

but generally are thin and show a highly irregular pattern of

sulfur and trace-element distribution. Conversely, "upper delta

plain-fluvial" coals are low in sulfur, are thick locally, but are

commonly discontinuous laterally. However, most important seams in

the Appalachian area are in the transitional zone between these two

environmental settings. In this transition zone thick coals attain

a relatively high degree of lateral continuity and are usually low

in sulfur.

Contemporaneous tectonic influences are superposed on changes in

seam character attributed to variations in environments of

deposition. Rapid subsidence during sedimentation generally results

in abrupt variations in coal seams but favors lower sulfur and

trace-element content, whereas slower subsidence favors greater

lateral continuity but higher content of chemically precipitated

material.

The iron ores were sought diligently for the capabilities of the

Lower Coal Measures to furnish a proper supply for the charcoal

furnaces. However, no similar measure led to like development of

the coal seams. Ironic, as the coal fired furnaces were the ruin of

the charcoal furnaces. As forests disappeared and the ability to

create charcoal dwindled with the resources, the furnaces in the

lake Superior area developed the coal technology that changed the

way iron was produced.

How appropriate it is that you travel to Rock Avenue in Hanging

Rock to make the following calculations for this earth cache. You

will want to take note of the coal seams that run through the

horizons of the formation here at the road cut.

Answer the questions below and email them to us. Take a picture

of the rock cut with your GPS in the shot to post.

1. How many seams of coal can be identified from bottom to top

on the rock cut?

a. 2 b. 3 c. 4

2. Estimate how many horizons (Layers) of coal and other ore

(sandstone, limestone, clay) comprise this formation from top to

bottom.

a. 3 b. 5 c. 7

3. Shoot an elevation at the road level exposure of the

formation.

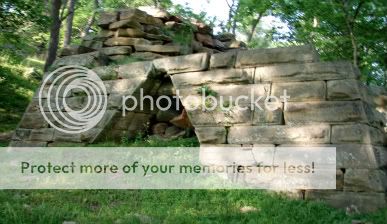

At the end of the 19th Century, the Hanging Rock Iron Region

began to fade away and the furnaces were blown out. Many furnaces

lie in ruin now.

Bigger furnaces capable of producing greater quantities more

efficiently through new technology saw the region's demise. 80

furnaces once dotted the 100 mile long 30 mile wide ore rich

region. Today there are only ruins and stories of what once was.

The area is still remembered as being the location of "where coal

met iron".