** Logging Requirments **

To get credit for this earthcache you must email me the answers to the following questions based on your observations at this area and reading the information below.

DO NOT POST ANY PICTURE WHICH WOULD PROVIDE THE ANSWERS TO ANY OF THE LOGGING REQUIRMENT QUESTIONS – they will be deleted and your log will be deleted!

- Which type of mining is done at this site, surface mining or underground mining? Please explain with details from what you SEE at this site why you choose your answer.

- Which type of ore deposit do you think exists at this location and explain briefly why you choose that type? (Intrusion, Sedex, MVT, or VMS deposit)

- Across the street from the production hoist headframe is another hoisting shaft, approximately how tall in height from the ground do you estimate this hoist shaft headframe to be?

The purpose of this Earthcache is to share with you a significant geological area in Smith County TN, where mining for this important resource occurs.

The mine at this location is referred to as the Cumberland Mine and was just reopened in 2010 by the Nystar Company. Nystar is the number one global zinc mining corporation and operates mines in many different countries with the only USA mines being in Tennessee. The Middle Tennessee operations consist of three zinc mines; Gordonsville, Elmwood , the Cumberland Mine and a processing plant, all located in Smith County, Tennessee. It is said that the three middle TN zinc mines produce some of the highest quality zinc in the world. Two additional bi-products at the mines are germanium and gallium. This mine makes it's main revenue from the sales of Zinc but it also brings in revenue from those two bi-products

This site, referred to as the Cumberland Mine was established in the 1990s. This specific mine employees about 87 employees working two shifts and operates 7 days a week. Presently this Cumberland Mine produces 2.5 million tonnes of ore deposits containing Zinc annually. A research statement conducted around 2008 indicated that this mine has ore reserves for zinc mining of 10 to 15 years.

How is it a company knows where to mine for zinc you ask? Well it was done statistically. In and around 1964 a New Jersey Zinc Company began explorations by drilling in Middle TN, Kentucky , Upper Mississippi Valley and Tri-state regions years ago. Multiple drill site samples were extracted from all areas and a statistical model was used to indicate the probable size of the ore bodies in each area. Based on these early explorations the three mines sites in Middle Tennessee , including this Cumberland mine, where described as "major zinc deposits". It took many more years and research to analyze the effects on any contaminators in the aquifers or surface waters and also the costs involved in mining the area.

Because this is an active mining operation trespassing is not allowed. So, the closet you can get to this mine is the public roadway at these coordinates. The huge structure that is visible is referred to as the headframe for the production hoisting shaft.

Geology of Zinc

A mineral deposit that contains enough minerals to be mined for a profit is called an ore. Ores are rocks that contain concentrations of valuable minerals. Zinc is commonly found in mineral deposits along with other base metals, such as copper and lead. Zinc deposits can be broadly classified on the basis of how they are formed. Zinc is produced mainly from four types of deposits: Intrusion related (high sulphidation, skarn, manto, vein),sedimentary exhalative (Sedex), Mississippi Valley type (MVT), and volcanogenic massive sulfide (VMS).

Intrusion related (high sulphidation, skarn, manto, vein) deposits are typically found in carbonate rocks in conjunction with magmatic-hydrothermal systems and are characterized by mineral association of calcium and magnesium. Typically the ore body contains more lead than zinc and is associated with silver. [1]

Sedex deposits account for more than 50 percent of the world's zinc resources and are formed when metal-rich hydrothermal fluids are released into a water-filled basin (usually an ocean), resulting in the precipitation of ore-bearing material within basin-floor sediments. The main host rocks associated with this type are shale, siltstone, and sandstone The world's largest zinc mine, the Red Dog mine in Alaska, is developed in a Sedex deposit. [2]

MVT deposits are found throughout the world and get their name from deposits that occur in the Mississippi Valley region of the United States. The deposits are characterized by ore mineral replacement of the carbonate host rock; they are often confined to a single stratigraphic layer and extend over hundreds of square kilometers. The dominate host rocks are limestone and dolomite. MVT deposits were a major source of zinc in the United States from the 19th century through the mid-20th century. [2]

In contrast to Sedex and MVT deposits, VMS deposits have a clear association with submarine volcanic processes. They also can contain significant amounts of copper, gold, and silver in addition to zinc and lead. The "black smoker" sea vents discovered during deep ocean expeditions are examples of VMS deposits being formed on the sea floor today.[2]

Methods of mining

Geologists need to find the ore deposits that are hidden underground. Different geologic processes concentrate mineral resources. They study geologic formations searching for areas that are likely to have ore deposits. They test the physical and chemical properties of soil and rocks. For example, they might test rocks to see if the rocks are magnetic or contain certain chemical elements. Then, geologists make maps of their findings to locate possible ore deposits. Today, satellites do some of the work for geologists. Satellites can make maps of large areas more quickly than geologists on the ground can.

After a mineral deposit is found, geologists determine how big the ore deposit is. They also calculate how much of the valuable minerals they think they will get from mining the deposit. The minerals will only be mined if it calculated to be profitable. When the price of zinc is low and it is not profitable to mine for zinc the mining operations will shutdown for a period of years. Then when zinc prices rise high enough the mines will re-open. The Smith County TN zinc mines just reopened for production in 2010 due to the rise in zinc commodity prices.

Once it is determined it is profitable to mine the ore, geologists with help decide the way it should be mined. The two main methods of mining are surface mining and underground mining.

Surface Mining

Surface mining is used to obtain mineral ores that are close to Earth's surface. The soil and rocks over the ore are removed by blasting. Typically, the remaining ore is drilled or blasted so that large machines can fill trucks with the broken rocks. The trucks take the rocks to factories where the ore will be separated from the rest of the rock. Surface mining includes open-pit mining, quarrying, and strip mining.

As the name suggests, open-pit mining creates a big pit from which the ore is mined. The size of the pit grows until it is no longer profitable to mine the remaining ore. Strip mines are similar to pit mines, but the ore is removed in large strips. A quarry is a type of open-pit mine that produces rocks and minerals that are used to make buildings. [3]

Underground Mining

Underground mining is used for ores that are deep in Earth's surface. For deep ore deposits, it can be too expensive to remove all of the rocks above the ore. Underground mines can be very deep. The deepest gold mine in South Africa is more than 3,700 meters deep (that is more than 2 miles)! There are various methods of underground mining. These methods are more expensive than surface mining because tunnels are made in the rock so that miners and equipment can get to the ore. Underground mining is dangerous work. Fresh air and lights must also be brought in to the tunnels for the miners. Miners breathe in lots of particles and dust while they are underground. The ore is drilled, blasted, or cut away from the surrounding rock and taken out of the tunnels. Sometimes there are explosions and sometimes mines collapse as ore is being drilled or blasted.[3]

Everyday Uses of Zinc

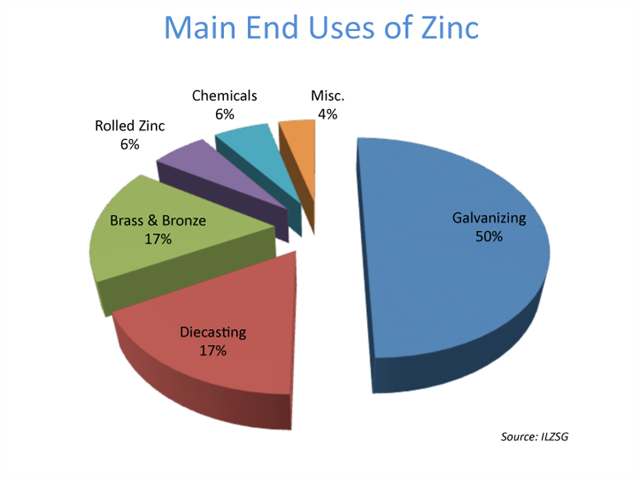

Zinc ranks as the fourth most widely used metal in the entire world behind iron, aluminum and cooper. Some typical uses of zinc include; zinc galvanizing, alloy combining, zinc oxide and also for human health. The construction industry relies heavily on zinc in such items as galvanized bolts, roofing and down drains. Similarly, zinc has great applications in the electrical and engineering industry in the form of brass and bronze.

[4]

[4]

First of all, Because of the strong anticorrosive properties of Zinc and its ability to bond with other metals so well it is used in zinc galvanizing. Galvanizing is the process of adding a thin layer of zinc to other metals such as iron or steel to prevent rusting. You can see how important this is in the construction or automobile industry for structures constantly exposed to the weather or salt stray from the oceans. One method of galvanizing is called 'hot-dipping' which is the process of dipping steel parts until there are totally submerged into a bath of molten zinc. Note the melting point of zinc is 787.15°F. At present, about one-half of all mined zinc is used for this purpose of galvanizing.

Because zinc is a transition metal it has two electrons in it's outer most shell of each atom that allows for a strong bond with other elements. This bonding allows for Zinc to become an alloy by combining it with other metals, such as combining zinc with cooper to make brass. Ancient romans made brass for coins, kettles and other decorative items. Likewise, a concentration of 90% copper and 10% zinc creates the alloy bronze. Similarly, zinc when combined with tin and lead will make solder which is useful in electrical components and pipes.

Zinc also has very important health contributions as all human beings need trace amounts of zinc to thrive. It is important to note that 'trace mineral' means you only need a small amount, as to much of any trace mineral would be toxic. Beef and seaford such as oysters naturally contain zinc. Vitamin supplements of zinc are said to significantly reduce the length of the common cold, though medical research still debates this. It is not benefial to intake to much zinc. There are different formula preparations with zinc included that do everything from preventing bad breath, diaper rash relief to formulas for anti-dandruff shampoos. Zinc oxide is a main ingredient in popular diaper rash creams, causing a protective barrier against the skin in a sticky cream form.

Now that you have learned what Zinc is, where Zinc comes from and what it is used for try to think of all the places in your life where you come in contact with Zinc.

References:

[1] http://www.zinc.org/basics/zinc_natural_occurrence

[2] http://geology.com/usgs/uses-of-zinc

[3] http://en.wikibooks.org/wiki/High_School_Earth_Science/Mining_and_Using_Minerals

[4] http://www.zinc.org/basics/zinc_uses